We develop, design and install special machinery

INDIVIDUAL SOLUTIONS FOR YOUR CHALLENGES IS OUR INCENTIVE

Our know-how

Lamination and edge-wrapping technology at the highest stage

Relay on our experience in special machinery and tool production for automotive interior industry. Our know-how means more efficiency in your workflow because of high quality and time-saving process.

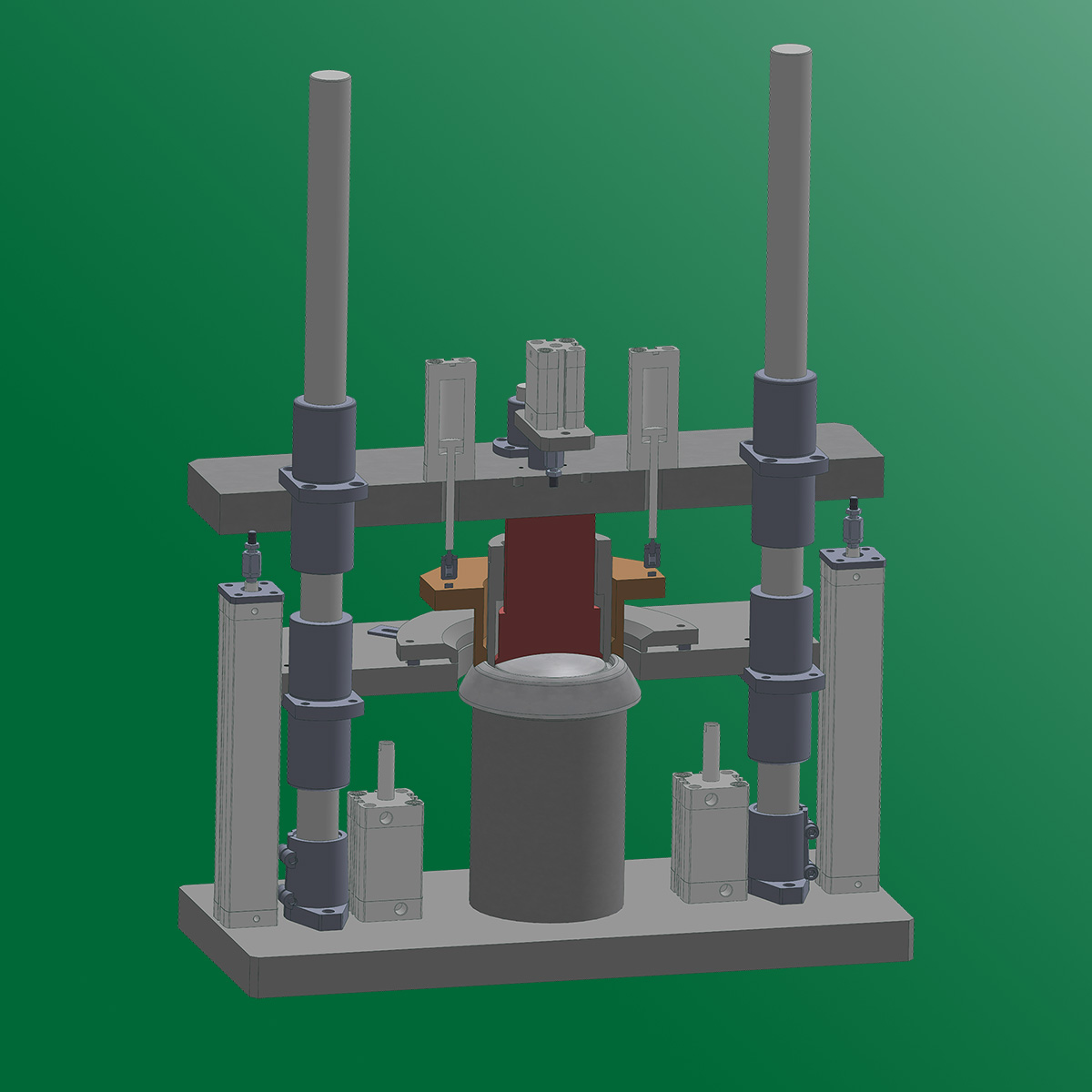

Steering wheel airbag cap

- One-/two-piece leather with or without decorative stitching

- Dispersion or hotmelt glue

- Milled seam guides in the tool or on a separate pre-fixing unit

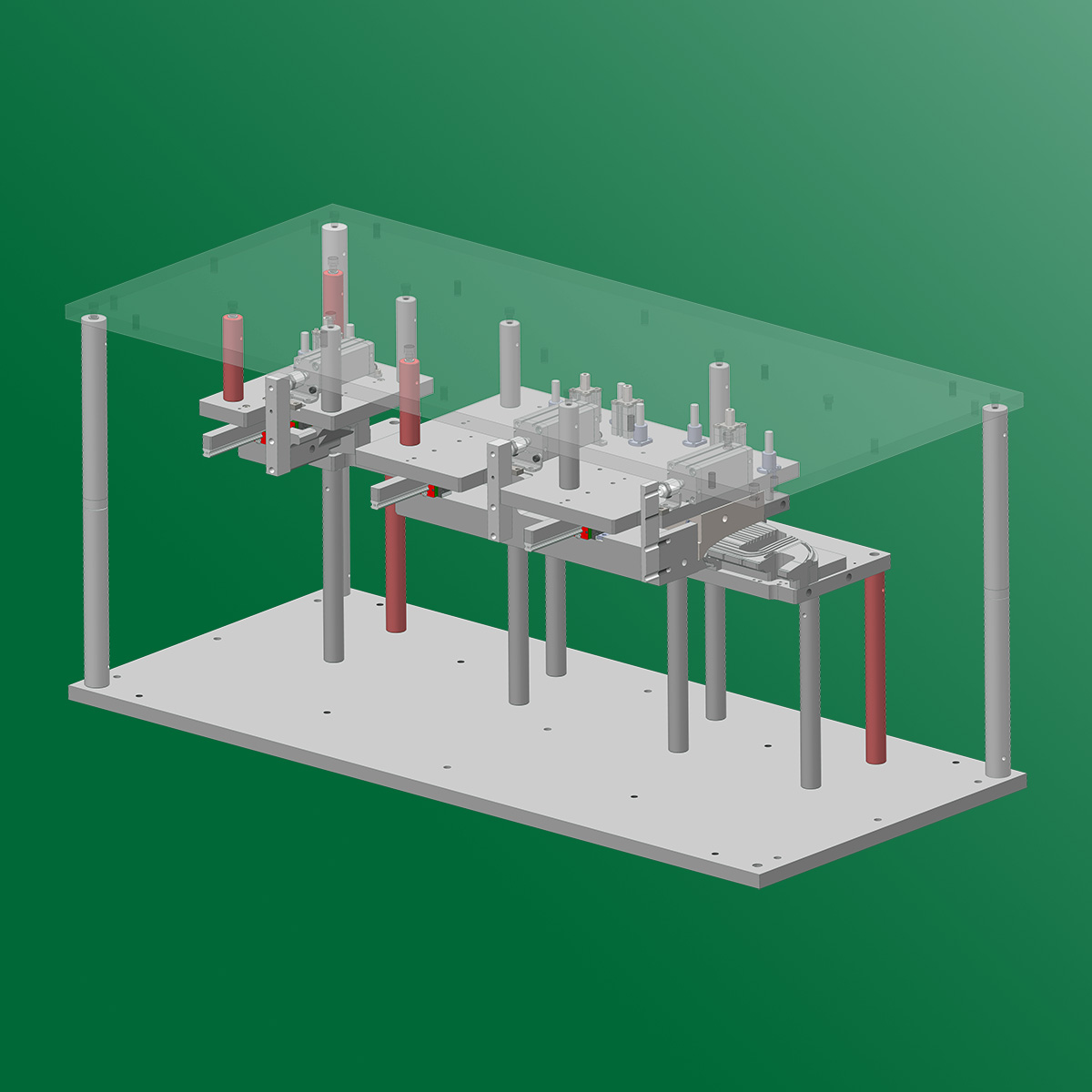

IP instrument panel, glove box top cover, floor room covering

- Natural or artificial leather

- Dispersion or hotmelt glue

- Pre-fixing units with milled seam guides

- Laminating- and edge-wrapping tools

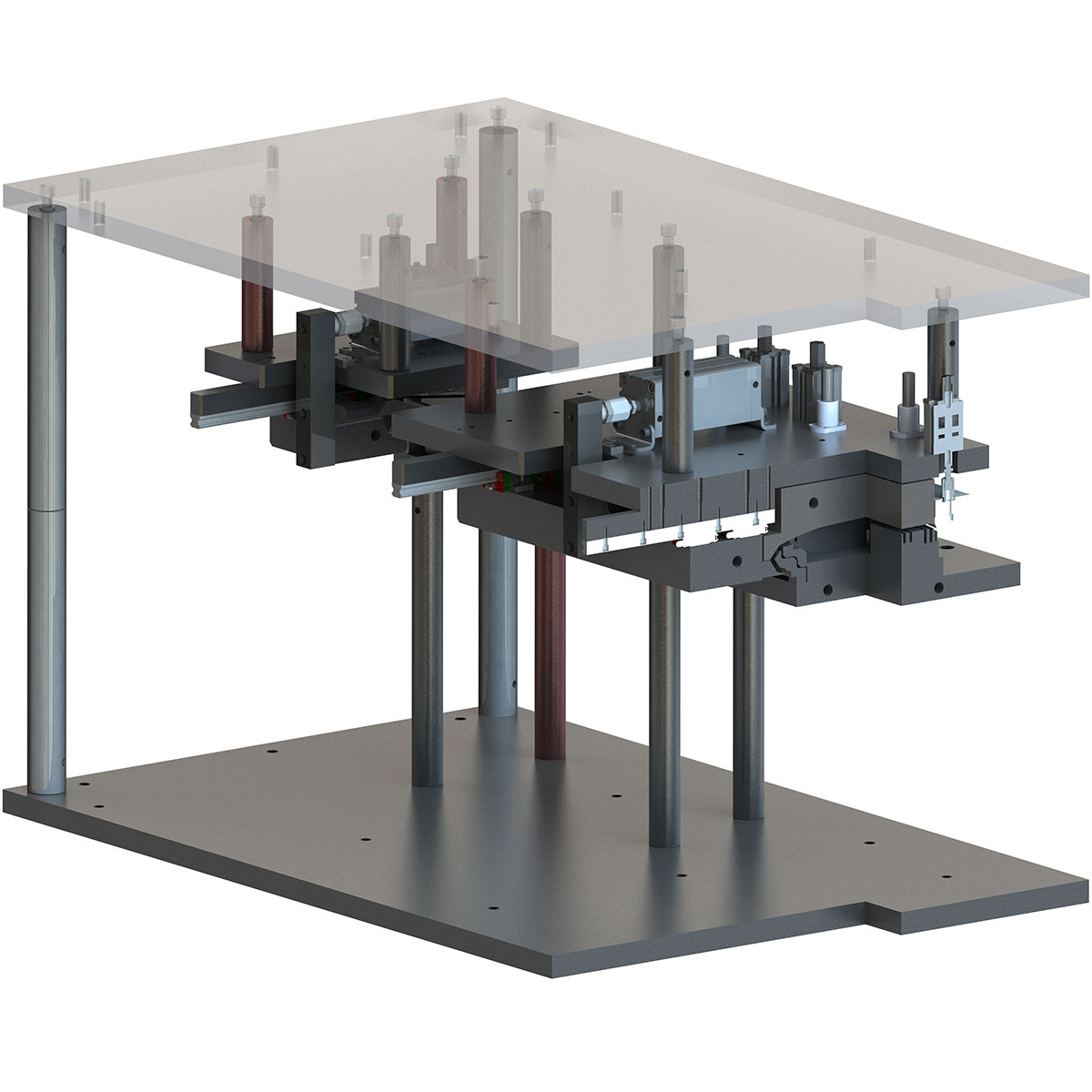

Center console, door cover, armrest, chair back cover, headliner

- Pre-fixing units with milled seam guides

- Mounting devices for headliners backside attaching parts

- Edge-wrapping tools for sunroof area

- Alcantara and Dinamica

Parcel shelf, rear trunk floor, bass speaker box

Carpet, artificial leather, fabric

Cover adjustment within the laminating tool

Laminating and edge-wrapping tool

Cover layout detection

Performance

VS Sondermaschinenbau GmbH devlops, designs and installs special machinery according your requirements.

Design of tools and machines with 3D CAD

Pneumatic and electric diagram

CAD-CAM individual production with reliable partners

Assembling and commissioning

Robot applications and programming of all robot brands

PLC programming

Delivery and global commissioning on-site

Summary

Pre-fixing units

Edge-wrapping tools

Press laminating tools

Assembling units

Decor stamping systems

Glue application units

Special machinery

Automation & Turnkey

3D print service

As part of our R&D and machine building we have a Keyence AGILISTA 3200w high-resolution 3D printer in our technical centre_2. With this printer we produce prototypes for our feasibility studies and trials and small series for our machines.

For service we offer to our clients the possibility to produce such articles as subcontractor. For this we use your CAD data or we could also design the articles for you according your technical specification. The printing time and material costs will be estimated with modelling software and the design costs will be offered according our expenses.

- High resolution ink-jet technology for high precision and solid articles because of a material layer thickness of only 15 µm to 30 µm

- Ca. 1 cm layer building / h

- 128 print nozzles, 4 print heads

Tolerance < ± 0,1 mm [/fusion_li_item][fusion_li_item icon=""] Printing with UV curing without temperature for articles with minimal water absorption and free from distortion [/fusion_li_item][fusion_li_item icon=""]Article dimension up to A4 x 200 mm; bigger parts can easily be designed to be screwed, glued or mechanical assembled out of various parts[/fusion_li_item][fusion_li_item icon=""] Four materials available:

- Stable, tear- and break-proof, transparent acryl material

- Up to 105 °C permanently temperature-resistant material

- Silicon Shore A 35 with very good reset force, compression set and elongation of break

- Silicon Shore A 65 with very good reset force, compression set and elongation of break

- All materials are water resistant and non silicone can be pigmented, painted, labelled with print or laser and metallized

References and partners

VS Sondermaschinenbau GmbH

Hans-Kramer-Straße 8

78187 Geisingen / Gutmadingen+49 (0) 7704 3588881